|

PPS Technologies |

|

The new leader in Barrier Coat Process Paint Stripping |

What we offerA superior, new generation of barrier coats that dry to harder films and reduce transference to painted parts. Advanced barrier coats that reduce chemical costs and lower energy costs by 20% or more. |

Why Barrier Coats?To reduce solvents in the repetitive decorative painting process. Barrier coats are a blend of buffered, water soluble polymers that are used in the process of removing water-based and solvent-based paint overspray from metal masks, tooling and fixtures, in repetitive decorative painting. What’s right for me?To help you choose the correct product and process information for your system Click here. Choose the product by selecting the paint type being stripped and capacity of your system. All options offer Defoamer 1 as an “as needed” over the side add-in. To help you with your mask tooling and washers, Click here. |

|

To contact us: |

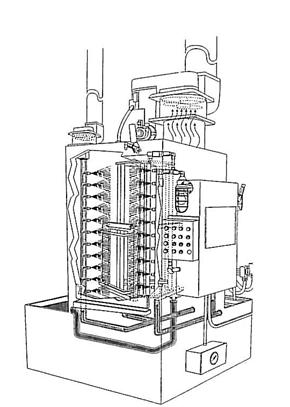

Who we arePPS Technologies was formed to combine the talents and experience of decorative painters, paint equipment and mask builders, and industrial process chemists to build solutions for the decorative painting industry. History shows that the individual paths of those involved in this industry have crossed many times. Barrier coat stripping of paint masks was first introduced to industry in the early 1970s. Barrier coats were used to replace solvents used in mask cleaning. The equipment and barrier coats evolved in the late 1980s from tank type soak units with silicates as barrier coat chemistry to pressurized spray systems with polymer based barrier coats. In the industry further development of the equipment and chemistry was put on the shelf for years.

|

|

PPS Technologies LLC PO Box 45 Carmel, IN 46082 Phone: 419-469-5530 Email: orders@pps-technologies.com |

|

Finally, in 2007 an experienced team came together to make a combined effort to improve the mask washing process equipment and find more effective polymers to make better barrier coats. After years of combined equipment development activities and a search for better barrier coat chemistry, PPS Technologies is proud to bring our products to the public.

Today, equipment is available with improved spray patterns and more efficient heating and energy use. Combining the latest masking equipment technology and our advanced polymer based barrier coats, provides the repetitive decorative painting industry with the most cost effective and easy to use solution on the market today. |